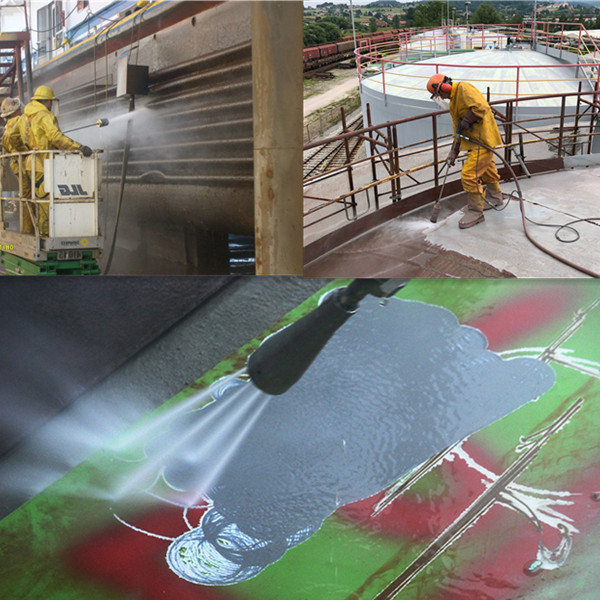

Ultra High Pressure Water Blasting For Rust Removal

Ultra High Pressure (UHP) of up to 40K psi (2750bar) water blasting services, is simply the practice of using highly pressurized water to remove a coating or contaminant from a substrate.

Q: What are the advantages of UHP Water Blasting Equipment?

A: There are numbers of advantages of Ultra High Pressure Water Blasting Equipment such as

- Reduction of Plant Downtime

- Labour Saving

- Plant Protection

- Water Conservation

- No Need of Chemicals and Non-Hazardous Materials

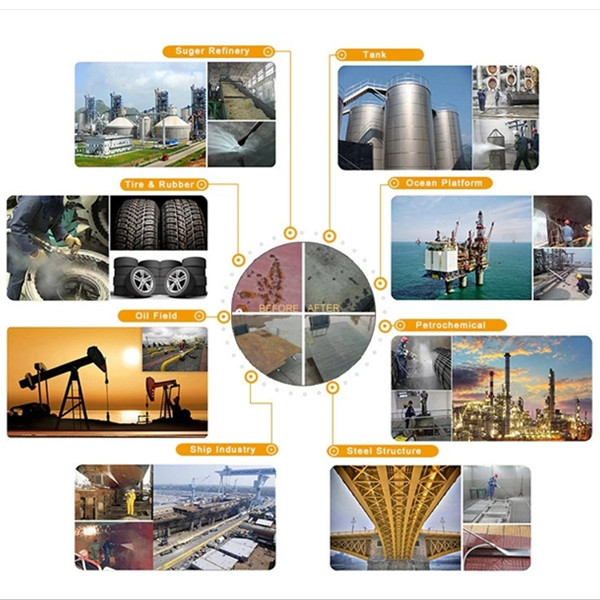

Q: What are the applications of Ultra High Pressure Water Blasting Equipment?

A: There are numbers of industrial applications of Ultra High Pressure Water Blasting Equipment. List of Hydro Blasting Applications:-

- Paint Removal

- Ship Hull Cleaning

- Concrete Demolition (Hydro Demolition)

- Cloride Removal From Concrete

- Asbestos Removal with High Pressure Water

- Pool refurbishment

- Investment Casting Cleaning

- Removal of Deposits in Pipes

- Rust Removals

- Marine Surface Preparation

- Kiln Cleaning in Cement Plant

- Pavement Overlay Preparation

- Concrete Surface Preparation

- Tank Cleaning with Special Nozzles

- Deburring with High Pressure Waterjet

High Pressure Cleaning Heat Exchanger Tube

Tube Cleaning offers high pressure water blasting services with 10,000(700bar) to 20,000(1400bar) PSI. High pressure water blasting is used to remove hard build up from an array of surfaces and equipment types. Water blasting has a multitude of applications such as tank cleaning, pipeline cleaning, paint removal, heat exchanger tube cleaning, heat exchanger bundle cleaning, and many others.

Clearing tubes needs to be performed regularly to ensure efficiency of the unit.

If slime or algae build up is present, using high pressured water to blast it away may do the trick (hydro blasting). For larger deposits of sludge and tougher buildups it may be necessary to use a mechanical method of cleaning.

Multifield Industrial Cleaning

10000-30000psi (700-2000bar) Aluminum: clean the hard scale, filter, water tank, container in the pipeline.

10000-40000psi ( 700-2750bar) Automotive: Removal of spray paint on paint shop grilles, derusting and deburring, cleaning of welded seams, cleaning of conveyor chains, brake lines, electrolytic cells, hydraulic lines, casting cleaning.

10000-40000psi ( 700-2750bar) Aviation: Removal of grease, rubber marks, marking lines and hydraulic fluids on runways.

5000psi (350bar) Cement plant: cleaning grate, floor, external piping, walls, hopper trucks and handling equipment dirt.

5000-36000psi ( 350-2500bar) Construction: Removal of concrete to expose steel bars, cleaning of stone walls, removal of expansion joint fillers, removal of laitance from floors, removal of various coatings from walls and floors such as: paint, asphalt, plastics, growths and corroded surfaces, Grows and treats concrete and stone surfaces, cuts concrete structures, cleans concrete moulds, pipes.

5000-40000psi(350-2750bar) Chemical plants: internal cleaning of autoclaves, reactors, pressure vessels, stirring tanks, oil storage tanks, distillation columns, cleaning filters, condensers, boilers, evaporators, bubbling trays, air filters, dryers, etc.

5000-7250psi (350-500bar) Marine: Removing marine life, crustaceans, algae .

Removing rust and paint from ship hulls, cement inside pipes on offshore oil rigs, cleaning pipelines and oil storage tanks on rigs . 30000-40000psi (2000-2750bar)

2900-30000psi (200-2000bar) Municipal: cleaning of sewers, drainage pipes, curbs, road markings.

Car Wash

Seeing a clean car is always attractive and also makes it last longer. Keeping your car clean can be a challenge and takes time. You have several options: go to a carwash, use a hose, bucket, and sponge, or use your pressure washer. Pressure washers are a great way to clean your car. The higher water pressure ensures that dirt comes off, and cleaning the underside of your vehicle using other methods is difficult. But the water pressure should not be so high that you can damage your paint or other parts.

Roof Cleaning

Roof pressure wash services can certainly clean up the area, but not all roof materials are best suited for pressure washing. While certain soft washing processes are possible, it’s often best to employ a professional roof cleaning company to do the work to prevent damage such as:

- Compromising bonding, adhesives or the underlayment of the roofing materials.

- Roof leaks around skylights, flashing or other roofing areas with joisted or worn seals.

- Breaks or cracks in clay, shake, slate, cement and metal roofs.

- Stripping away the granules on asphalt shingles.

- Accidentally dispersing fungus, moss and other organisms from one part of the roof to the rest of the area.

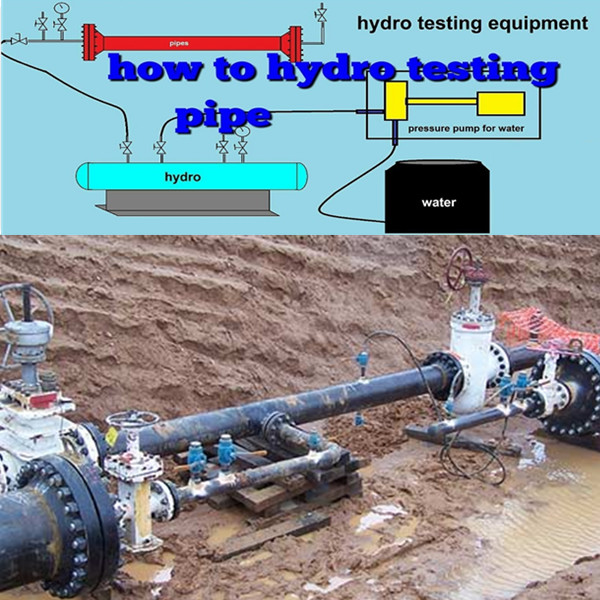

Pipeline Test

How Pressure Testing Works ?

To conduct a hydrostatic pressure test on its gas pipeline , first obtains all needed work permits, coordinates with local agencies and provides gas to customers temporarily from an alternative source .

- the section of pipeline to be tested in excavated , vented of gas and cut open at both ends , the inside is mechanically cleaned before testing .

- A”test head” a picece of pipe with a hose and one end, is welded to one end of the undergrand pipe being tested . another test head is attached to the other end of the tested section.

- the pipeline is filled with water through the hose.

- the pipeline is pressurized to a specified pressure , much higher than normal operating pressure- for example 6000psi if maximum allowable pressure 4000psi .

- the test pressure is held and monitored for at least eight hours.

- pipe sections that fail the test are replaced with new pipe that has already passed a pressure test.

- pipe is emptied of water , dried and returned to service .

Boiler Test

Hydro testing a boiler is one way to check that you have proper seals on the tubes, flanges, fittings, and connections. This test takes place on new boilers or after any major pressure vessel work. To begin the test, a hydro pump is used to help fill the boiler with water. The water is pumped into the vessel to the maximum allowable working pressure (M.A.W.P.) and brought to 1.5 x the M.A.W.P. It is recommended to not use cold water to hydro test a boiler.

If you use cold water it will cause the metal tubes to shrink and leak. It is best to let the water sit for approximately 24 hours before performing the test so the water will warm up. After the boiler is filled with water it will be inspected for leaks. If the boiler has any leaks, the needle on the gauge will drop. A service company will typically perform the hydro test and a technician will sign off that the boiler has either passed or failed the inspection.

MISCELLANEOUS – Pressure Test of Piping System

1. Subject to permission lines which are to be tested with their service fluid may be subjected to an initial service leak test.

2. Pressure‑relief valve which is calibrated shall be provided in order that excess test pressure can be escaped.

3. Lines containing check valve shall have the source of pressure located in the piping upstream of check valve so that pressure is applied under the seat. If this is not possible, check valve disk shall be removed or located open.

4. Expansion joints of the sliding sleeve or bellows type shall be provided with temporary restraint if required for additional load under-test, or shall be isolated from the test.

5. Prior to start test, the piping system shall be checked that all the valve discs are located suitable open and closed position, and the vents and drains are installed properly for the test.

6.The following items shall be isolated or block them out of the test. Field tests of these items, when required, are covered by their respective specifications; equipment, machinery, Relief valves, Rupture discs, Flame arrestor, Displacement meters, Rotameters, Pressure gauges, Gage glasses, Filter and strainer elements and Control valves with close tolerances. Steam traps, internals and any items not designed to with stand the pressure.

– All instrument control piping down stream of first piping block valve

– All orifice plates which interfere with filling, venting and draining shall be removed from the test.